Ice Rink Cooling System

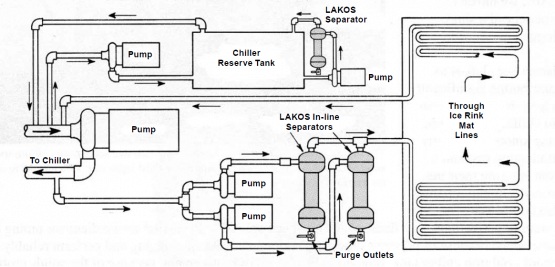

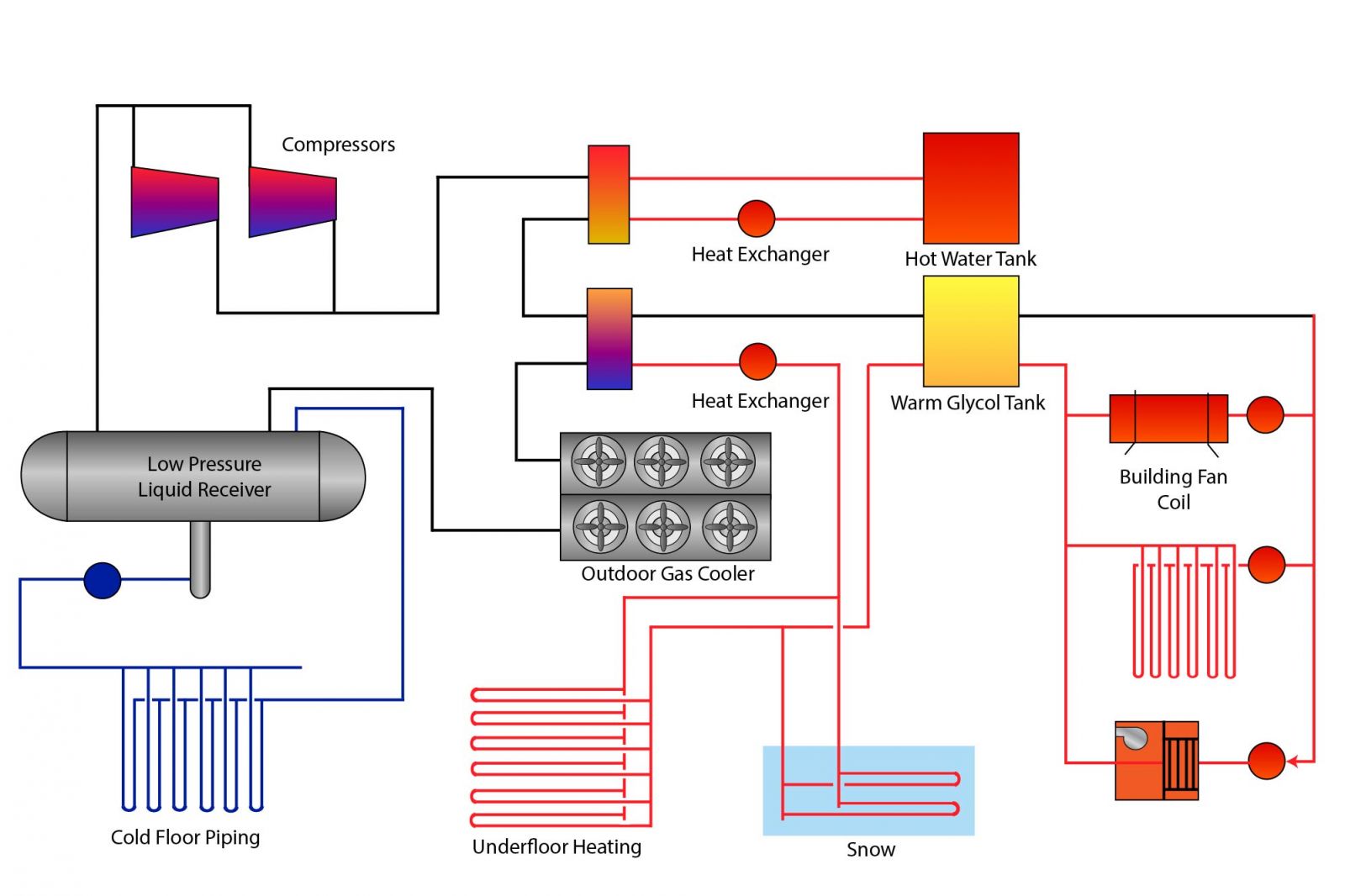

Ice rink cooling system. Glycol or calcium chloride brine. For the closed loop the ice temperature is supplied to the refrigeration system model from an external file based on measurements. The three chillers cool the brinewater to 16 F -9 C and provide up to 270 tons of cooling see How Air Conditioning Works for the definition of a cooling ton.

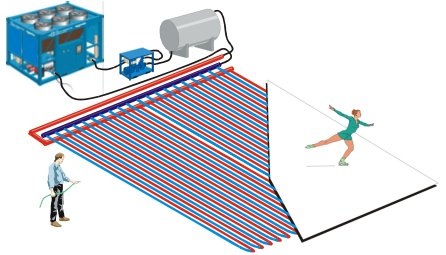

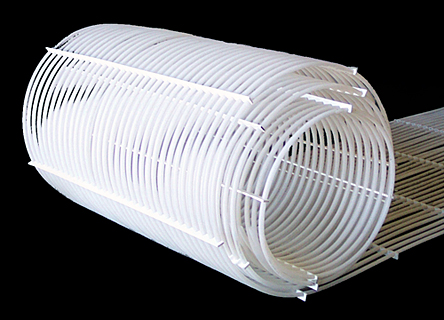

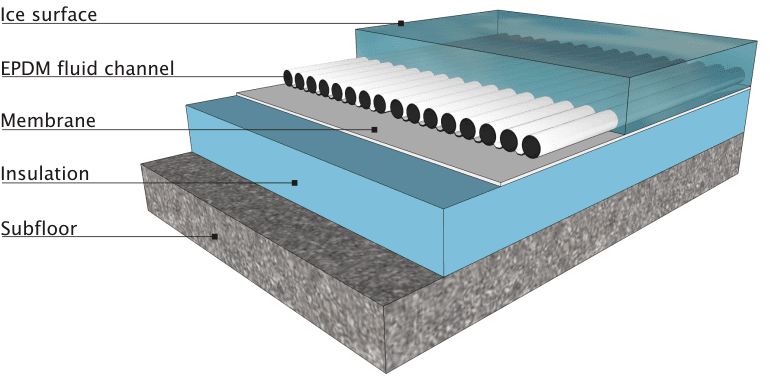

The refrigeration system is indirect with ammonia as refrigerant calcium chloride 24 -. Backyard chiller ice rinks consist of a chiller and a network of piping which serves to pull heat from the rink surface above effectively cooling the water until it forms a slab of ice suitable for skating. If needed go to Refrigerated Backyard Rinks to bone up on how the chillers refrigeration works.

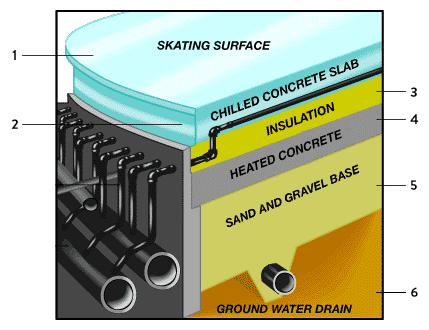

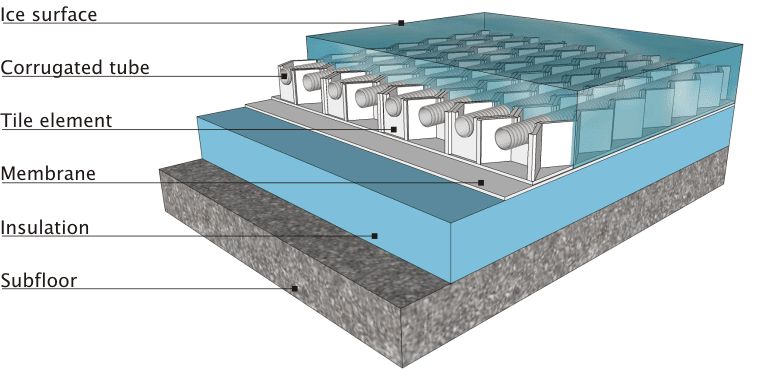

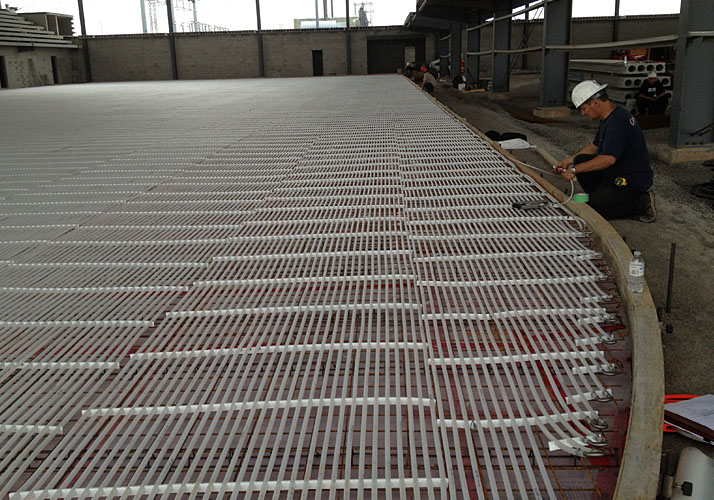

On an ice skating rink the ice temperature should be maintained between 6 and 1 and cooling should be provided by circulating saline solutions in tubes or tubes to ensure that the ice surface has a required hardness for different types of ice sports. Can be more efficient and effective than air cooling. Live Active Leisure demanded an environmentally friendly and efficient system to replace the existing R22 system.

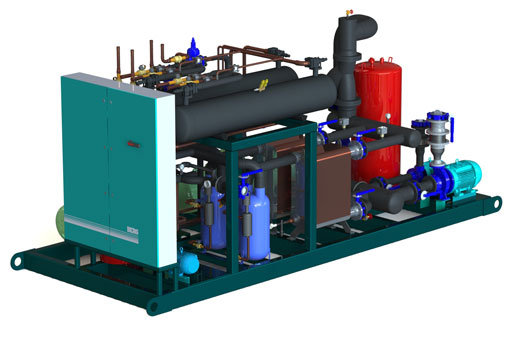

Two GRAM reciprocating compressors with total nominal cooling capacity of 400 kW and 90 kW. Features of Freon Skid Mounted Ice Rink Chillers include. As the rink is filled with water an electric chiller pumps ice-cold heat transfer fluid like propylene glycol through the pipes extracting heat from the surface of the rink.

A refrigerated ice rink utilizes an ice rink chiller that draws the heat out of the ice ensuring it stays frozen despite temperatures rising well above freezing. Yet the chiller wont run if the ice sensor reads a temperature below its threshold of operation. Ice rink cooling systems work by utilizing a network of pipes arranged below the surface of the rink.

Ice Rink Chillers Features include. We will work with you and your team to discuss your needs to find the perfect solution to regulate your rink. A mechanical failure at the Glenwood Springs Ice Rink disabled the cooling system leading to the shutdown of the facility for the foreseeable future and cancellation or relocation of all programming just as local youth hockey programs get underway.

The extra cooling capacity should enable the rink which often had to close on warm days when the ambient temperature caused the ice to melt to offer consistent hours of operation. To maintain the level and quality of ice an Ice Rink Chiller is specifically designed that operates to maintain the low freezing temperature and avoid any slightest variation in regulating the ice rink.

A refrigerated ice rink utilizes an ice rink chiller that draws the heat out of the ice ensuring it stays frozen despite temperatures rising well above freezing.

We will work with you and your team to discuss your needs to find the perfect solution to regulate your rink. The compressor horsepower is estimated based on design conditions. A typical Refrigerated Rink System is comprised of a chiller refrigerated mats manifold box and a rink frame constructed. Ice rink cooling systems work by utilizing a network of pipes arranged below the surface of the rink. Simultaneous Heating and Cooling. Glycol or calcium chloride brine. For the closed loop the ice temperature is supplied to the refrigeration system model from an external file based on measurements. We offer a wide range of chillers and sizes from small quiet chillers for residential ice rinks to air and water cooled commercialindustrial chillers for larger full size or multiple ice pad facilities We also build geothermal chillers and custom designs for site specific heat recovery and thermal storage ice rink applications. The chiller is where the brine returns with heat from the ice rink surface to be absorbed by the much colder liquid refrigerant ammonia.

The actual billed electricity demand must be inferior or equal to this value. Ice rink cooling systems work by utilizing a network of pipes arranged below the surface of the rink. This arrangement consists of a closed refrigeration loop by connecting the brine temperature leaving the chiller 2 to the brine temperature entering the slab Figure 712. The installed electrical power of the cooling and heating systems represents most of the ice rinks electrical demand. The UKs ice rinks are experiencing something of a renaissance resulting in an increasing number of outdoor temporary rinks a feature in many town centres. The extra cooling capacity should enable the rink which often had to close on warm days when the ambient temperature caused the ice to melt to offer consistent hours of operation. The ice 3 low temperature water source heat pumps were designed to produce refrigeration and heat simultaneously and have the flexibility to provide both low temp and medium chilled glycol.

Post a Comment for "Ice Rink Cooling System"